Cerca le soluzioni di compost granulato di cui hai bisogno!

5-10% Ora spento!

-PRODUTTORE DI ATTREZZATURE PER FERTILIZZANTI YUSHUXNIN

Forniamo le migliori soluzioni e macchine per granulati per te

Con più di 20 anni di esperienza nella produzione di macchine avanzate per la granulazione del compost. Le attrezzature per fertilizzanti YUSHUNXIN guadagnano la fiducia e gli elogi dei clienti in patria e all'estero.

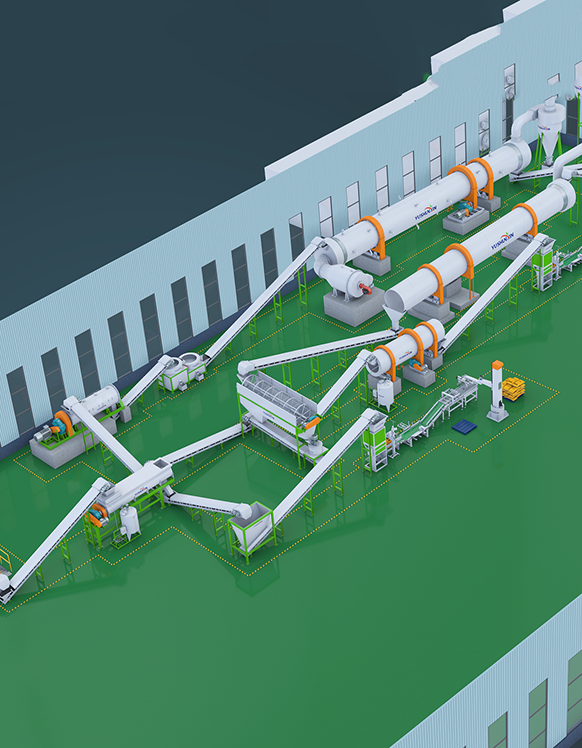

Le ultime soluzioni di compost granulato

Scopri l'ultima progettazione di soluzioni di compost granulato nell'azienda di apparecchiature per fertilizzanti YUSHUNXIN. Ottieni il miglior piano e macchinari per pellet di compost granulare per te.

perché scegliere noi

Se desideri acquistare l'attrezzatura per il tuo progetto di compost o pellet di fertilizzante organico, YUSHUNXIN Attrezzature di ingegneria

Casi di produzione di fertilizzante compost granulare

Ci sono alcuni casi dei nostri clienti passati per la configurazione di impianti di produzione di fertilizzanti compost granulati come riferimento.

Contattaci

Notizia & Domande frequenti

Sia le notizie industriali che quelle aziendali sono qui. E tutto quello che vuoi sapere sulle attrezzature e sulle tecnologie per la pellettizzazione del compost.

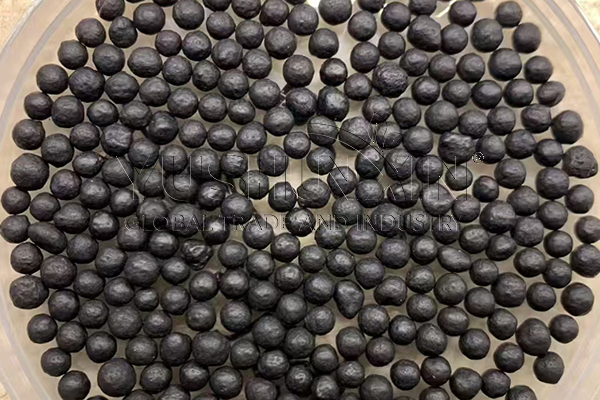

È possibile produrre pellet di concime organico tondo con granulazione a doppio rullo?

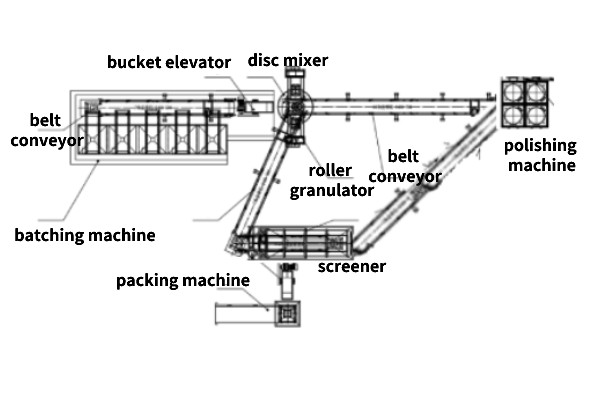

SÌ, assolutamente. IL granulatore a doppio rullo il processo forma denso, granuli di fertilizzante compost uniforme. Quindi utilizzando il lucidatrice per fertilizzanti dopo la granulazione migliora la rotondità dei granuli del fertilizzante. Con questa semplice aggiunta, il vostro sistema di granulazione a secco per la lavorazione del letame compostato può produrre prodotti premium, pellet sferici di fertilizzante organico. Che sono adatti per l'imballaggio e l'applicazione sul campo.

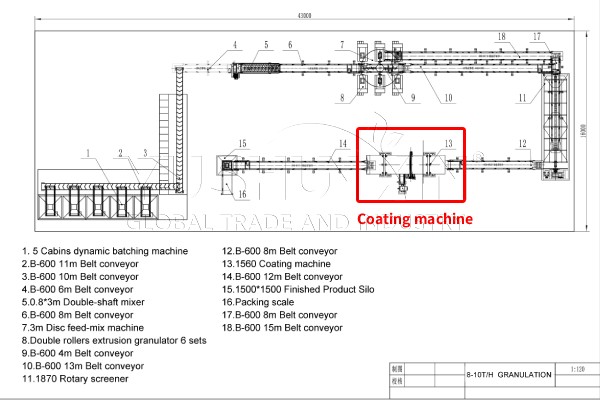

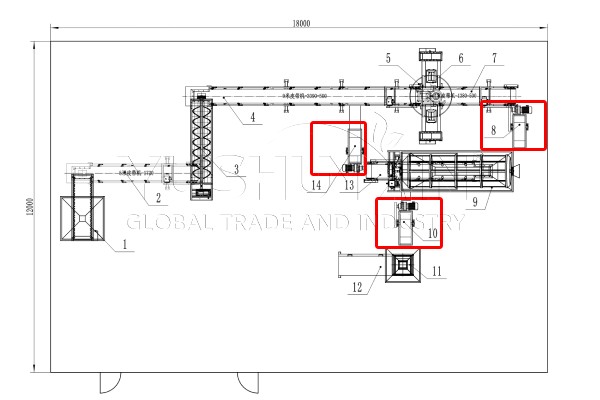

Qual è la progettazione di una linea di produzione di fertilizzanti a sfere rotonde con granulazione per estrusione a secco?

Qual è il design di una linea di produzione di fertilizzanti a sfere rotonde granulazione per estrusione a secco?

Inoltre, in base alla tua attrezzatura, possiamo offrirvi soluzioni personalizzate di granulazione a rulli per la produzione di pellet di fertilizzanti organici sferici. Ad esempio, puoi aggiungere il sistema di asciugatura per ridurre rapidamente il contenuto di umidità, IL spalmatore di pellet di fertilizzante per elaborare bio fertilizzanti o concimi a lenta cessione, ed elevatori a tazze per un migliore utilizzo dello spazio negli impianti più piccoli. Vieni a realizzare il tuo piano di produzione di compost in granuli.

Quanto costa una linea completa di granulazione a doppio rullo per la produzione di fertilizzanti organici a sfere rotonde?

Il prezzo totale della linea di produzione di fertilizzanti organici rotondi dipende dalla capacità richiesta:

| Capacità (T/H) | Costo stimato (Dollaro statunitense) |

|---|---|

| 1-5 | $50,000–$100.000 |

| 5-10 | $100,000–$180.000 |

| 10-20 | $180,000–$300.000 |

Se il tuo budget è limitato, è possibile acquistare solo il granulatore a rulli e la lucidatrice. Questo sistema compatto produce ancora pellet di fertilizzanti rotondi pronti per il mercato.

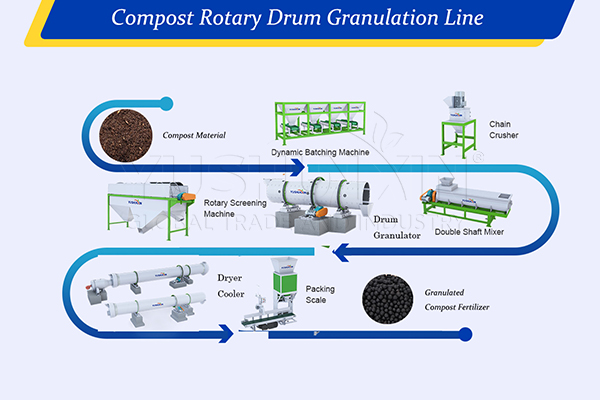

Oltretutto, esistono anche altri sistemi per trasformare il compost in pellet di fertilizzante organico di forma rotonda YUSHUNXIN. Ad esempio, linea economica di granulazione a dischi, piano di granulazione industriale a tamburo rotante, sistema di pellettizzazione a denti agitati per la produzione di granuli duri, ecc. Non esitare a contattarci per loro immediatamente!

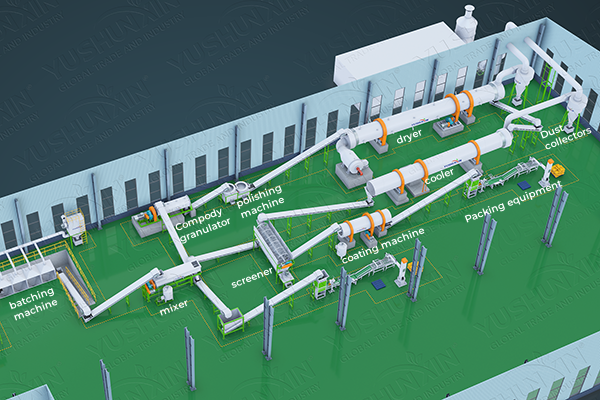

Qual è il processo per produrre pellet di fertilizzante a lenta cessione dal compost?

Generalmente, preparazione del compost in granuli di fertilizzante con prestazioni a rilascio lento contiene 5 parti.

Insomma, consiste l'intero sistema per produrre pellet di fertilizzante a lenta cessione dal compost 8 attrezzatura. Macchina dosatrice, trituratore di compost, miscelatore, pellettizzatore, asciugatrice, più fresco, macchina di rivestimento e attrezzatura per l'insaccamento. Questi fertilizzanti compost organici pellettizzati, quando applicato al suolo, rilasciare gradualmente i nutrienti, sostenere la crescita delle piante per un periodo prolungato.

come aggiungere agenti a rilascio lento quando si producono pellet di fertilizzante a rilascio lento dal compost?

Per incorporare la funzionalità a rilascio lento con il fertilizzante compost granulare, ci sono 2 modi per la tua scelta.

Miscelazione prima della granulazione del concime a lenta cessione

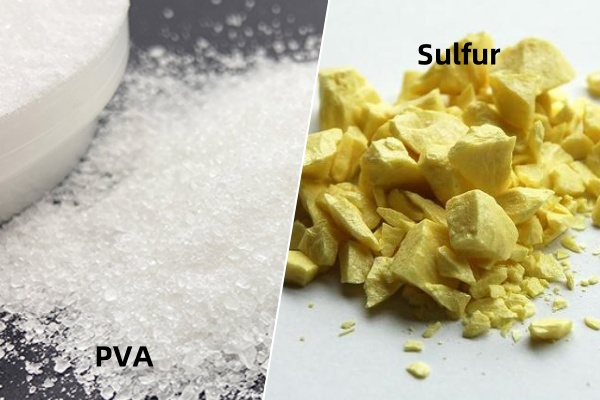

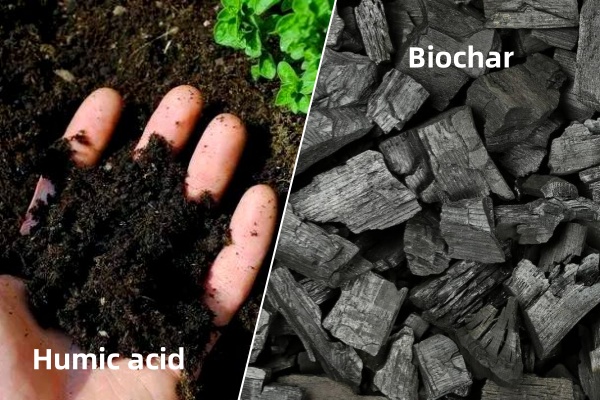

Per prima cosa, è possibile miscelare gli additivi a lento rilascio nel materiale del compost prima della granulazione. Dopo che il compost è stato frantumato e vagliato, gli additivi (acido umico, biochar, ecc.) e i leganti vengono miscelati uniformemente in un mixer per compost orizzontale o verticale. Ciò garantisce una distribuzione uniforme e prestazioni costanti nel prodotto finale.

Aggiunta di agente a lento rilascio durante la pellettizzazione del compost

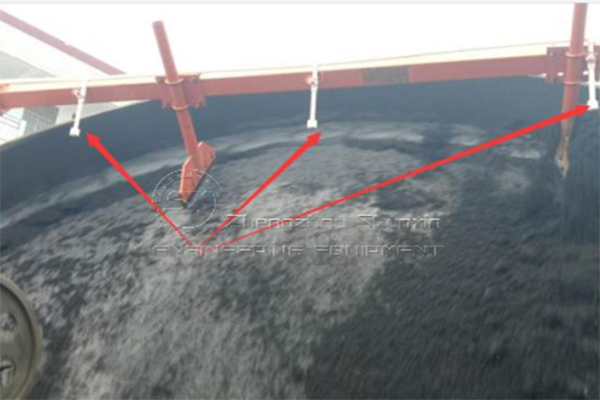

Inoltre, ci sono anche macchine per pellet di compost con dispositivo spray. Compreso un granulatore a tamburo rotante e un pellettizzatore a dischi. Possono aggiungere agenti a lento rilascio durante la granulazione del compost. Questo è adatto a chi necessita solo di un granulatore di fertilizzanti a lenta cessione.

Rivestimento con pellicola ad agente distaccante

Per un altro, puoi anche scegliere di utilizzare a spalmatrice a tamburo rotante applicare strati esterni che rallentano il rilascio dei nutrienti dopo la pellettizzazione mediante un'apparecchiatura di granulazione del compost. Se prevedi di trasformare il compost granulato in fertilizzante a lenta cessione, questo metodo è consigliato.

Quanto tempo impiega il fertilizzante a rilasciare lentamente??

I fertilizzanti a lenta cessione ottenuti dal compost in genere iniziano a funzionare entro tre-dieci settimane, poiché i microrganismi scompongono lentamente i nutrienti. Questo processo graduale garantisce che le piante ricevano un apporto costante di nutrienti essenziali nel tempo. Alcuni fertilizzanti a lenta cessione possono continuare ad essere efficaci per alcuni mesi, e in alcuni casi, fino a un anno, fornendo nutrimento a lungo termine e riducendo la frequenza di riapplicazione. Ciò li rende ideali per mantenere una crescita sana delle piante con il minimo sforzo. COSÌ, ci sono molti produttori di fertilizzanti che investono in progetti per produrre pellet di fertilizzanti a rilascio lento dal compost.

Se vuoi saperne di più sulle soluzioni e sulle macchine per la produzione di compost granulato, non esitare a contattarci immediatamente. Esistono piani di granulazione del compost che vanno da 1 operazione t/h A 20 produzione t/h, da pellet di sterco di mucca A granulazione del compost di rifiuti minerali, ecc. a vostra scelta.

Come riciclare particelle di dimensioni non qualificate per il ritrattamento nel processo di granulazione del compost?

Generalmente, la velocità di produzione del pellet di compost delle dimensioni richieste può essere raggiunta 90%-95% con Pellet di compost YUSHUNXIN. Può garantire una perdita di materiale minima. Ancora, per granulare davvero il compost senza rifiuti, il resto 5%-10% di fertilizzante compost granulato, troppo grande o troppo piccolo, deve essere adeguatamente riciclato. Comunemente, ha solo bisogno 2 passi.

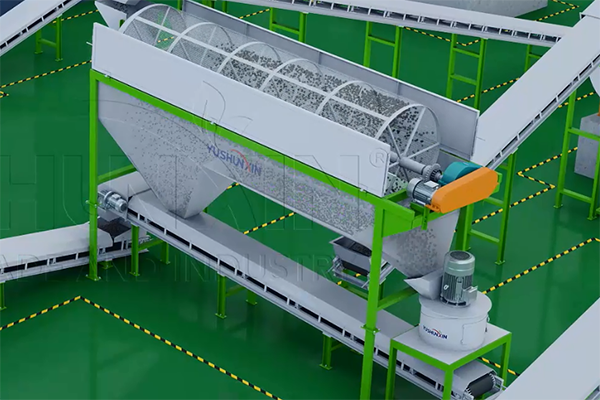

Separare i granuli di compost con le dimensioni richieste da quelli non qualificati

Primo, è necessario separare i pellet di fertilizzante compost granulato da quelli che non soddisfano le tue esigenze. Per questo, vaglio a tamburo rotante può finirlo perfettamente. Con rotazione delle maglie di setacciatura, può dividere il fertilizzante compost pellettizzato nella dimensione richiesta, troppo grande e troppo piccolo. Ci sono 1-20 modelli di vagliatori per compost con capacità t/h per te.

Frantumazione delle particelle di fertilizzante restituite in polvere fine

Prossimo, è possibile macinare i granuli di compost non qualificati in polvere fine da restituire alla macchina per la produzione di pellet di compost. For the returned compost pellets crushing the chain crusher is the best choice. Because of small space needed, you can put it closed to rotary screener directly. Vale a dire, it don not need extra belt conveyor.

This system can greatly reduce the material waste in compost granulation plant. If you need the unqualified compost pellet recycling system, welcome to contact us now!

Is there powder dust material recycling system for no waste compost granulation?

Besides granulated compost fertilizer returning, you also can reach zero waste by prevent dust generation. Per questo, YUHSUNXIN can offer you best solutions, which contains:

Professional dust collectors

Primo, the most effective solution to recycle the spread powder in compost granulation is use professional dust collectors. Including cyclone dust collectors, water curtain dust collectors, and dust fall rooms. Questi dispositivi catturano le particelle sospese nell'aria durante la produzione del pellet di compost, soprattutto nei passaggi di essiccazione e raffreddamento del compost. Il materiale del compost nel sistema di raccolta delle polveri può essere riciclato per preparare nuovamente il fertilizzante compost granulare.

Macchina fertilizzatrice con coperture antipolvere

Inoltre, per ridurre ulteriormente gli scarti nella granulazione del compost, puoi anche aggiungere coperture antipolvere sulla macchina dove la polvere di compost è più facile da spargere. Come il trasporto e la vagliatura del nastro. Qui, YUSHUNXIN può offrirti queste macchine personalizzate per granulare il compost senza rifiuti.

In sintesi, è del tutto possibile granulare il compost senza rifiuti. YUSHUNXIN può offrirti le migliori soluzioni. Non esitare a contattarci immediatamente per il tuo piano di produzione di fertilizzanti compost di granulazione.

Quali tipi di mulini a pellet per compost diesel sono disponibili in YUSHUNXIN?

Generalmente, per chi vuole produrre fertilizzante compost in pellet con aggiunta di materiale minerale, ci sono 2 le soluzioni sono apprezzate dai produttori.

Granulatore di fertilizzanti organici di nuovo tipo

Questo nuovo tipo di macchina per la granulazione di fertilizzanti organici è progettato per produrre in modo efficiente pellet di compost con elevata durezza. Il suo tasso di granulazione di 2-5 La produzione di pellet di fertilizzante organico da mm può raggiungere 95%. Allo stesso tempo, l'output del set singolo è 1-8 t/h, che può soddisfare pienamente la granulazione del compost organico su piccola e larga scala.

Granulatrice a doppio rullo

Ma, la scelta migliore per produzione di pellet di compost secco È attrezzatura per granulazione a doppio rullo. Questa macchina utilizza rulli per comprimere i materiali del compost in pellet di fertilizzante organico solido. Non c'è quasi acqua coinvolta. È particolarmente efficace per la granulazione del compost senza essiccazione e per avviare il progetto in aree scarse d’acqua.

Mulino a pellet a testa piatta

IL mulino a pellet a stampo piatto è un'opzione più compatta per operazioni di granulazione del compost più piccole. È facile da usare, facile da mantenere, ed altamente efficiente per convertire il compost organico in pellet di fertilizzante uniforme. COSÌ, è ideale per aziende agricole o aziende appena avviate.

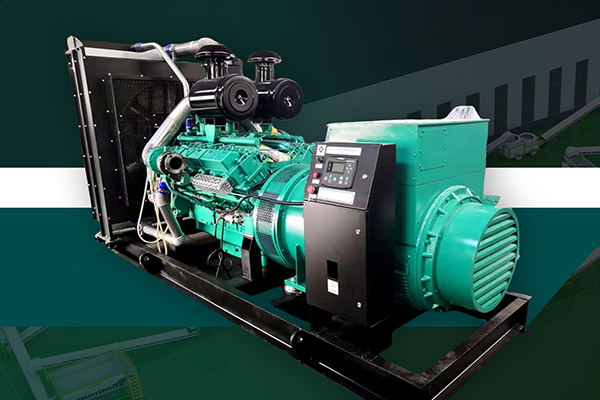

Is there solution to generate powder for the whole granulated compost making line?

Ovviamente. Besides diesel compost pellet making machines, YUSHUNXIN also prepare large diesel powder generator. This can supply enough electricity for the whole compost granulation line working. Comunemente, there are various models of powder generators for your choice.

If you have any other requirements for compost granules making, welcome to contact us now.

Quanto costa a 5 Costo della linea di produzione di granuli di compost in t/h?

Stai cercando attrezzature per il tuo impianto di granulazione di fertilizzanti compost? Il pellettizzatore a disco è la scelta ideale quando si hanno i seguenti requisiti:

Generalmente, un completo 5 Linea di produzione di granuli di compost t/h con prezzi del pellettizzatore per vaschette compresi tra $120,000-$170,000. Comunemente, contiene la macchina di alimentazione del materiale, frantoio per compost, miscelatore di fertilizzanti, apparecchiature per granulazione in padella, asciugatrice, più fresco, macchina imballatrice, raccoglitore di polveri, ecc. Il preventivo preciso dei progetti della linea di pellettazione del compost. Ad esempio, è necessario compostare o no, coperture antipolvere, acciaio al carbonio o materiale in acciaio inossidabile, ecc.

Qual è il costo operativo dell'impianto per la produzione di granuli di compost al giorno in Russia?

Dopo aver acquistato le macchine della linea di granulazione del compost, è necessario considerare il costo per il funzionamento di un impianto di granulazione di fertilizzanti organici compost. Questo di solito contiene il pagamento dei lavoratori, costo dell'energia elettrica, investimento nel carburante, ecc.

Qui, prendi quanto sopra 5 Linea di produzione di granuli di compost in t/h come esempio. Se costa Rs 500 per uomo/giorno , potere a Rs 7/ kwHr , Combustibile di scarto agricolo a Rs 10/kg , Olio per forni a Rs 45/kg, ecc.

Il costo approssimativo dell'impianto di granulazione del compost per un giorno è di 38668,8 Rs = 500 Rs*4 lavoratori+ 154.8 Kw*Rs7/KwHr* 8 ore+350 kg*Rs 10*kg *8 ore.

A condizione che desideri ottenere costi operativi più precisi della linea di granulazione del compost organico che acquisti, welcome to contact us now. Inoltre, se vuoi conoscere altri aspetti sulla configurazione dell'impianto di produzione di compost pellet, YUSHUNXIN può anche offrirti le migliori soluzioni e risposte. Inclusa la soluzione in polvere per l'attrezzatura per fertilizzanti, altri prezzi di linea per la produzione di compost granulato e così via.

Quanta quantità di compost produrre?

Prima di tutto, come suggerisce il nome, è necessario garantire il volume di rifiuti organici da trattare. Quando desideri acquistare una grande attrezzatura per il compostaggio da oltre 10 Impianto di granulazione compost t/h, il rivoltatore di compost a ruota è la scelta migliore. Perché ha un arco di svolta di 8-30 me profondità di svolta di 1-3 M.

Quale metodo di fermentazione della macchina per compostaggio su larga scala desideri acquistare?

Nel mercato, esistono varie macchine per la produzione di compost su larga scala. Adottano diversi metodi di compostaggio e tecnologie di fermentazione. Qui, devi acquistare quello migliore in base alle tue esigenze.

quanto costa la macchina per il compost su larga scala?

Grazie alla grande capacità e alla tecnologia avanzata per un migliore compostaggio, i prezzi delle macchine per compostaggio su larga scala sono intermedi $20,000-$60,000. Come accennato in precedenza, il rivoltatore di compost a ruota è il più economico. Generalmente, UN 10 m compost copre un prezzo $33,600

qual è il materiale dell'attrezzatura per il compostaggio su larga scala?

Comunemente, al fine di ridurre l'erosione derivante dalla grande produzione di compost attrezzature per la fermentazione dei fertilizzanti, produrremo un corpo macchina per compostaggio di grandi dimensioni acciaio al carbonio, che ha un'elevata resistenza. Inoltre, per le parti di rotazione del compost, aggiungeremo un film di vernice anticorrosione. Oppure possiamo sostituirlo con acciaio al manganese e acciaio inossidabile in base alle vostre esigenze.

Che tipo di materiale di scarto organico decomporre?

Generalmente, L'attrezzatura per la fermentazione dei fertilizzanti YUSHUNXIN è adatta a quasi tutti i tipi di compostaggio dei rifiuti organici. Ad esempio

Perciò, sia che tu acquisti il grande rivoltatore di compost per fertilizzanti per la gestione dei rifiuti organici o per la produzione di granuli di compost commerciale, le nostre attrezzature per la produzione di massa di compost possono soddisfare pienamente le vostre esigenze.

Come trovare il produttore affidabile di compositori su larga scala

Dopo aver determinato il tipo di macchina per la fermentazione di grandi dimensioni che desideri acquistare, è consigliabile trovare un produttore affidabile di macchine per compost. È meglio avere i seguenti vantaggi:

Fabbrica di origine per attrezzature per il compost di fertilizzanti

Perciò, puoi ottenere il prezzo favorevole per acquistare le grandi attrezzature per il compostaggio.

Premuroso servizio post-vendita

Soluzioni tempestive per l'installazione del rivoltatore di compostaggio, operazione, produzione di compost, ecc.

Seguendo questi passaggi, puoi prendere una decisione ben informata quando acquisti una macchina per il compostaggio su larga scala, garantendo che soddisfi le vostre esigenze operative di produzione di fertilizzanti per compost e contribuisca efficacemente ai vostri obiettivi di produzione di pellet di compost.